BCN3D Printing Filaments

BCN3D Printing Filaments are formulated to deliver highest results for BCN3D Printers. The filaments are Industrial Grade in quality.

Manufactured by BASF & Mitsubishi Chemicals to ensure highest print quality to cover most of the technical Proto / End Use requirements.

Available

Under Development

BCN3D Printing Filaments - Standard

Easy / Multipurpose / Multi-Color

Overview

PLA (Polylactic Acid) is a biodegradable, sustainable and food safe polymer made from organic sources.

It is the most common used filament in FFF 3D printers for its ease of use and wide range of applications, specially those not mechanically or thermally demanding. Definitely a good starting point to learn about the 3D Printing manufacturing process.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Architectural mockups

- Aesthetic, concept models

- Investment casting molds

- Low mechanically demanding prototypes

Properties

- Detailed and glossy surface quality

- Good tensile strength

- Rigid, fragile behaviour

- Good UV resistance

- Withstand operating temperatures up to 50°C

- Odor-free, ideal for educational and office environments

- Compatible with PVA supports

- Low solvent and water resistance

How to print

45º C Epsilon

For BCN3D Cura users:

Get a proper printing profile for PLA using the ones integrated into the BCN3D Cura. Download the latest version of BCN3D Cura.

Bed adhesion:

To ensure good bed adhesion use Magigoo.

Recommendations:

- Store it in an airtight container with desiccant.

Impact resistant / Stiff / Easy to print

Overview

Tough PLA (Polylactic Acid) is engineered for its high impact resistance and strength, similar to those of ABS, in combination with the stiffness of PLA. This material shows excellent results in layer adhesion and is the perfect match for tooling or manufacturing aids where a high impact is needed. Tough PLA is an easy to print material with a very good surface quality.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

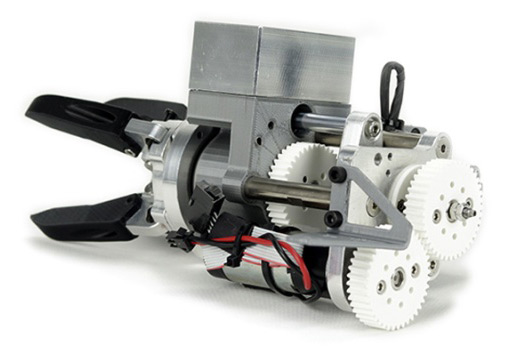

- Manufacturing aids

- Manufacturing tools

- Functional prototyping

- End-use parts

- Alternative to ABS for large prints

Properties

- High impact and stiffness

- Easy to print

- Excellent surface quality

- Alternative to ABS

How to print

For BCN3D Cura users:

Get a proper printing profile for Tough PLA using the ones integrated into the BCN3D Cura. Download the latest version of BCN3D Cura.

Bed adhesion:

To ensure good bed adhesion use Magigoo.

Recommendations:

Store it in an airtight container with desiccant.

Moisture resistant / Heat resistant / Easy

Overview

PET-G (Polyethylene terephthalate glycol-modified) is a polyester thermoplastic characterised by a good balance of tensile strength and elongation at break. Its high resistance to water and chemicals makes it the material of choice for water-tight containers and protective cases.

PET-G is a versatile technical material, as easy to print as PLA, but with an improved balance of mechanical, chemical and thermal properties.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Parts in contact with salts, acids and alkalis

- Functional prototypes and mechanical parts

- Waterproof applications

- Structural parts subject to mild stress

- Snap-fit joints

- Commonly used in beverage bottles

Properties

- Resistance to corrosive chemicals

- Good balance of strength, impact resistance and elongation at break

- Great dimensional stability and toughness

- Good glossy surface quality

- Good abrasion resistance

- Water and moisture barrier

- Withstand operating temperatures up to 70°C

- Low rate of ultrafine particles (UFP) and volatile organic compounds (VOC)

- Compatible with PVA supports

How to print

For BCN3D Cura users:

Get a proper printing profile for PET-G using the ones integrated into the BCN3D Cura. Download the latest version of BCN3D Cura.

Bed adhesion:

To ensure good bed adhesion use Magigoo.

Recommendations:

Enclosure is recommended for BCN3D Sigma and Sigmax printers.

Flexible / Wear resistant / Tough

Overview

TPU (Thermoplastic polyurethane) is an elastomeric copolymer, made up of alternating soft and hard blocks, which give hardness and flexibility at the same time. This material is ideal for those applications where flexibility and durability are highly desired.

With Shore-A hardness of 98, TPU is a resistant material for several industrial applications, both mechanical or chemical. Moreover, it’s been especially designed to improve the 3D printing experience.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Industrial seals, gaskets, sleeves or hinges

- Soft-touch multi-material models or handles

- Flexible-joined multi-material models

- Protective cases Shoe soles, non-slip surfaces

- Springs, seals and shock absorbers

- Wheels and rollers

Properties

- Improved thermal stability to avoid jamming and degradation issues

- Dissolves easily with ordinary water

- Compatible with most 3D printing filaments

- Better printability

- Moisture sensitive

- Biodegradable

How to print

For BCN3D Cura users:

Get a proper printing profile for TPU using the ones integrated into the BCN3D Cura. Download the latest version of BCN3D Cura.

Bed adhesion:

To ensure good bed adhesion use Magigoo.

Recommendations:

- Store it in an airtight container with desiccant Dry filament before printing.

- Place it in an oven or in a dehydrator at 60-70ºC for 6 to 8 hours.

- Recommended sequencial printing: print one object at a time because travels leave residual material

Hidrosoluble / Support material / Easy

Overview

PVA (Polyvinyl alcohol) is a water-soluble thermoplastic, widely adopted as a support material for FFF 3D printers. Optimized for the FFF manufacturing process, our PVA is compatible with most of BCN3D filaments and can be easily printed to create the support and then dissolved with ordinary water.

PVA supports allow to achieve better surface quality, to orientate the part to get better mechanical properties and even to print multi-component models and mechanisms.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Exceptional adhesion with PLA

- Also great in combination with PET-G, TPU and Nylon

- Water-soluble supports for partially enclosed cavities and complex geometries

- Sacrificial moulds

Properties

- Improved thermal stability to avoid jamming and degradation issues

- Dissolves easily with ordinary water

- Compatible with most 3D printing filaments

- Better printability

- Moisture sensitive

- Biodegradable

How to print

For BCN3D Cura users:

Get a proper printing profile for PVA using the ones integrated into the BCN3D Cura. Download the latest version of BCN3D Cura.

Bed adhesion:

To ensure good bed adhesion use Magigoo.

Recommendations:

- Store it in an airtight container with desiccant.

- Dry filament before printing. Place it in an oven or in a dehydrator at 50ºC for 6 to 8 hours.

- Clean the hotend after you’ve used PVA, before starting printing with other materials.

Hidrosoluble / Support material / Wide compatibility

Overview

BVOH (Butenediol vinyl alcohol copolymer) is a water-soluble thermoplastic optimized for the FFF manufacturing process. Our BVOH extends the compatibility with most of BCN3D filaments and can be easily printed to create the support and then dissolved with ordinary water. In comparison with PVA, BVOH supports allow to achieve better surface quality, to orientate the part to get better mechanical properties and even to print multi-component models and mechanisms with a fastest dissolution and easier to remove.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Water-soluble supports for partially enclosed cavities and complex geometries

- Smooth finish on functional prototypes

- Sacrificial molds

- Movable mechanisms

- Hollow parts

Properties

- Water-soluble material

- Compatible with PLA, Tough PLA, PET-G, TPU 98A, ABS, PA and PAHT CF15

- Fastest dissolution

- Easy to remove inside small parts

- Less clogging issues

- Highly hygroscopic

- Biodegradable

How to print

For BCN3D Cura users:

Get a proper printing profile for BVOH using the ones integrated into the BCN3D Cura. Download the latest version of BCN3D Cura.

Bed adhesion:

To ensure good bed adhesion use Magigoo.

Recommendations:

- Store it in an airtight container with desiccant.

- Dry filament before printing. Place it in a hot air dryer or vacuum oven at 60ºC for 4 to 16 hours.

- Calibrate the printer to ensure a reliable adhesion between materials and a proper alignment of both printheads.

- Clean the hotend after long prints or when switching material.

Technical

Stiff / Impact resistant / Heat resistant

Overview

ABS (acrylonitrile butadiene styrene) is one of the most common technical materials in several industries around the globe. Its an engineering material which combines rigidity and resistance to impacts. It is the ideal material for technical applications and moving parts.

Traditionally a challenging material to print with FFF printers, it has been re-formulated to ensure good interlayer adhesion and to reduce warping. Our grade allows for excellent dimensional accuracy and high durability.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Parts under high mechanical stress

- Strong prototypes and end-use parts

- Aesthetic models

- Commonly used on electronic or appliances cases, suitcases and phones

- Precision fits, knobs, lids and buttons

- Rigid models with snap-fit joints

Properties

- Attractive matt surface quality

- Good stiffness and dimensional stability

- High impact resistance, even at low temperature (-10 ºC)

- Good heat resistance, up to 100 ºC

- Improved printability

- Water resistant

- Low resistance to organic solvents

How to print

For BCN3D Cura users:

Get a proper printing profile for ABS using the ones integrated into the BCN3D Cura. Download the latest version of BCN3D Cura.

Bed adhesion:

To ensure good bed adhesion use Magigoo.

Recommendations:

- Store it in an airtight container with desiccant

- Enclosure is required for BCN3D Sigma and Sigmax printers

- Once the part is printed, remove carefully the piece to avoid chipping the glass. The removal of the object is easier if you just apply water on the glass

Light / Moisture Resistant / Chemical Resistant

Overview

PP (Polypropylene) is a semycrystalline thermoplastic, known for its resistance to chemical agents. It is completely inert and does not easily interact with any substance, for this reason it is commonly used for the packaging of food and chemicals.

It is a flexible and durable material, with a high resistance to impacts and wear.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Ideal for light parts

- Commonly used in bottles, packaging and containers

- In automotive for non-structural areas of the body

- Plugs and stoppers

- Chemically aggressive environments

- Living hinges

- Pipes, joints and elements in contact with water

Properties

- Exceptional resistance to aggressive chemicals such as alkali, acids and organic solvents

- Lightweight and clear

- Flexible and resistant to impacts

- Durable and resistant to fatigue, even at low temperature (-20 ºC)

- Good thermal resistance, up to 100 ºC

- Hydrophobic, non-stick surface

How to print

For BCN3D Cura users:

Get a proper printing profile for PP using the ones integrated into the BCN3D Cura. Download the latest version of BCN3D Cura.

Bed adhesion:

To ensure good bed adhesion use Magigoo.

Recommendations:

Enclosure is recommended for BCN3D Sigma and Sigmax printers.

Wear resistant / Low friction / Impact resistant

Overview

PA (Polyamide) is an engineering plastic, characterised by its great resistance to impact and able to work continuously at a temperature of up to 120 ºC for an extended period of time.

Its semi-flexible behaviour derives from a semicrystalline structure, which impart strength and durability, best suited for the most demanding technical applications. A low coefficient of friction allows for a short-term use in contact with moving parts.

Compatibility: Find out the BCN3D printers and filaments compatibility

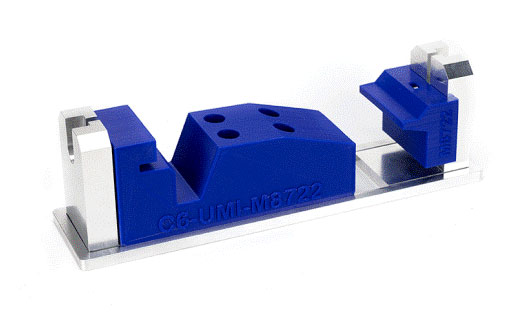

Applications

- Strong and flexible parts

- Structural components exposed to a harsh environment

- Parts demanding high fatigue endurance

- Bearings, nuts, rivets, washers and gears

- Cams, rollers, snap-fit joints and sliding components

- Plugs, connectors, jigs and fixtures

- Electronic covers and tool handles

Properties

- Exceptional impact resistance and good strength

- Low friction coefficient

- High abrasion resistance

- Thermal resistance (upt to 120ºC)

- Good resistance to oil and alkali

- Strongly hygroscopic

- Thermomechanical properties dependent on environmental humidity

How to print

For BCN3D Cura users:

Get a proper printing profile for PA using the ones integrated into the BCN3D Cura. Download the latest version of BCN3D Cura.

Bed adhesion:

To ensure good bed adhesion use Magigoo.

Recommendations:

- Store it in an airtight container with desiccant.

- Dry filament before printing.Place it in an oven or in a dehydrator at 50ºC for 6 to 8 hours

- Enclosure is required for BCN3D Sigma and Sigmax printers.

Composites

Light / Chemical resistant / UV resistance

Overview

PP GF30 (Polypropylene 30% glass fibre) is a composite filament, filled with glass fibre for chemically resistant, lightweight and dimensionally stable parts. It is amongst the most used filled materials in the automotive industry, characterised by a long service life and able to resist to all weather conditions.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Parts exposed to aggressive and humid environments or in contact with chemicals.

- Rigid structural elements such as brackets, bars, shafts and frames.

- Automotive and aerospace industry.

Properties

- Combination of excellent chemical resistance, strength and stiffness.

- Lightweight.

- Water and UV resistant.

- Resistant to aggressive environments and high temperature, up to 120 ºC.

How to print

For BCN3D Cura users:

Get a proper printing profile for PP GF30 using the ones integrated into the BCN3D Cura. Download the latest version of BCN3D Cura.

Bed adhesion:

To ensure good bed adhesion use Magigoo.

Recommendations:

Only compatible with BCN3D Epsilon when paired with the Hotend X.

High temperature / Stiff / Wear resistant

Overview

PAHT CF15 (High Temperature Polyamide carbon fiber reinforced) combines high temperature and chemical resistance with extreme mechanical properties.

It allows to work under 150ºC continuous temperatures with the peak temperature of 180ºC in comparison to a standard PA. 15% carbon fiber reinforcement makes it stiffer thus open new fields for the printing of demanding applications.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Structural and functional parts subject to high temperatures and aggressive environments.

- Metal replacement in the automotive industry.

Properties

- Exceptional resistance to aggressive chemicals such as alkali, acids and organic solvents

- Lightweight and clear

- Flexible and resistant to impacts

- Durable and resistant to fatigue, even at low temperature (-20 ºC)

- Good thermal resistance, up to 100 ºC

- Hydrophobic, non-stick surface

How to print

For BCN3D Cura users:

Get a proper printing profile for PP using the ones integrated into the BCN3D Cura. Download the latest version of BCN3D Cura.

Bed adhesion:

To ensure good bed adhesion use Magigoo.

Recommendations:

Enclosure is recommended for BCN3D Sigma and Sigmax printers.