Romax Technology provides world leading solutions for the design, analysis, testing, and manufacture of gearboxes, drive trains and bearings.

Benefits

Fast and efficient product design from the concept phase in a user-friendly model creation environment.

Flexible tool which integrates with CAD, MBD and CAE to reduce errors and time to market.

Empowering software enables informed engineering decisions early in the product development process.

Romax Concept

A rapid drivetrain design tool that enhances your early development process

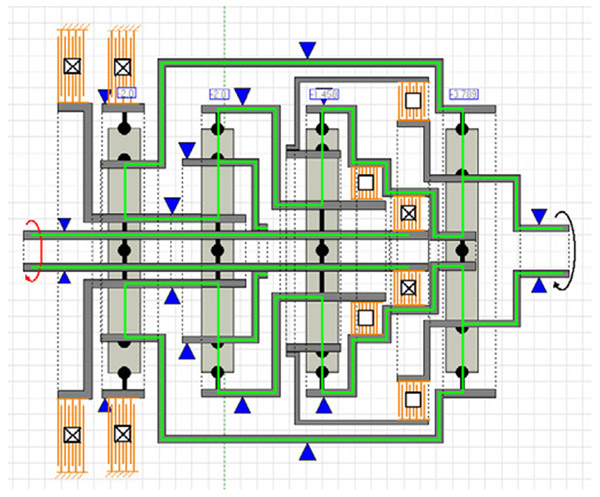

2D and 3D design and sizing is seamlessly combined with CAE simulation in an intuitive user interface to help designers explore innovative solutions and make confident engineering decisions at the early stages of product development.

Designs can be easily taken from Romax Concept and converted into CAD models and drawings, optimised multibody dynamic models and used in any other Romax Nexus product for more detailed analysis.

Key Features

Build multiple drivetrain layouts with ease thanks to an intuitive drag-and-drop interface.

Analyze the performance of each concept and manage trade-offs between durability, efficiency, NVH, packaging, weight, cost, etc.

Refine your design by selecting bearings directly from supplier catalogues and optimize gear ratios and macro-geometry.

Perform vehicle drive cycle analyses to evaluate system efficiency.

Integrate Romax Concept into your workflows with CAD import and export, automatic generation of multibody.

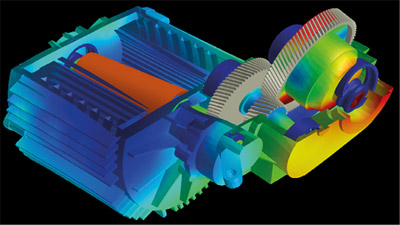

Romax Enduro

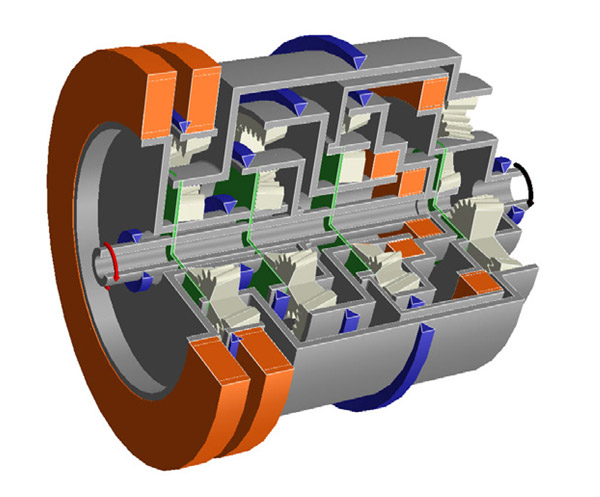

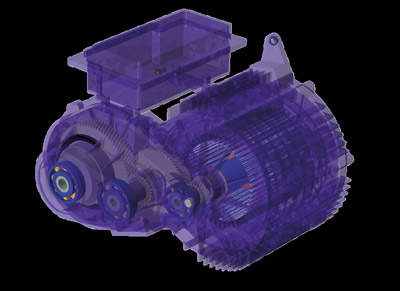

The industry standard for electro-mechanical drivetrain systems.

Dedicated, component-level modelling within a whole system:

Rapid, accurate & parametric component models

Comprehensive bearing catalogues

Gear design & optimisation tools

Import/create and condense FE components

Import/export geometry with CAD tools

XML and batch interface for model building and modification

Reporting:

Full system and component static results including deflections, loads and stresses

Detailed gear and spline contact results

Load case and duty cycle durability reports

Customised reporting

Component and system-level structural analysis:

Fast, parallelized static analysis of full driveline

World-class gear and bearing contact models

Flexible FE bearings & gear blanks

Gear root stress analysis

Batch running and parametric study

Electric machine unbalanced magnetic pull

Durability analysis:

DIN, ISO and AGMA rating Gear safety factors

Bearing life

Shaft fatigue

Splines

Synchroniser sizing

Duty cycles generation from measured data

Effect of manufacturing tolerances

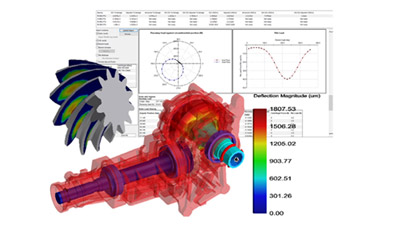

Romax Energy

Romax Energy: robust methods and tools for predicting transmission power losses, integrated with Romax Nexus and beyond

Comprehensive efficiency models to predict transmission power losses:

Calculate load-dependent and load-independent losses.

Use measured drive cycle data for analysis relevant to real-life operating conditions.

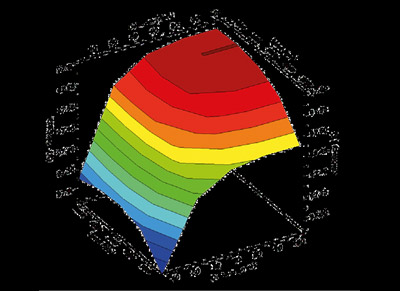

System-level reports – system efficiency maps, energy losses, equivalent fuel consumption and CO2 emissions.

Component-level reports – power losses, efficiency, fuel consumption and CO2 emissions.

Benefits

Meet efficiency targets by changing the design quickly, accurately and reliably, using Romax Energy’s comprehensive efficiency models to predict power losses

Design and optimise components for highly efficient designs by investigating and understanding the impact of varying geometric and operational parameters on the whole system performance

Accurately predict losses and the impact of the oil additive pack and friction modifiers on system efficiency, using our advanced tribological models and proprietary methods based on FVA345 methodology

Component and system-level design for optimal efficiency:

Parametric study to investigate the impact of parameters (e.g. torque, speed, temperature, lubricant level) on system efficiency.

Calculate component power loss using widely-used industry methods and our own world-leading proprietary drag models.

Investigate gear and bearing efficiency and redesign accordingly.

Understand efficiency at the powertrain level and work with other Romax Nexus products to manage trade-offs with durability and NVH.

Select or design the optimal oil for efficiency performance:

Choose from an extensive lubricant database, customise lubricant parameters or create your own.

Advanced tribological models (FVA 345 and gear micro geometry methods) offer accurate prediction of the lubricant’s effect on system efficiency.

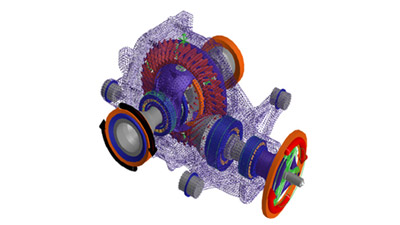

Romax Spin

Romax Spin: insight through cutting edge analysis and simulation of rolling element bearings

Modelling:

Quickly and easily build a detailed, parametric electro-mechanical system model, including shafts, bearings, gears, splines, clutches, housings, and electric machines

Search supplier catalogs directly and choose from more than 60,000 bearings from SKF, Schaeffler, Timken, JTEKT, and Nachi

Model fully customisable bearings of all ball and roller types, including all external, internal dimensions and micro-geometry

Specify ring flexibility, clearance and press fits, preload, internal clearance, mounting distortion, temperatures and other assembly and operating properties.

Analysis:

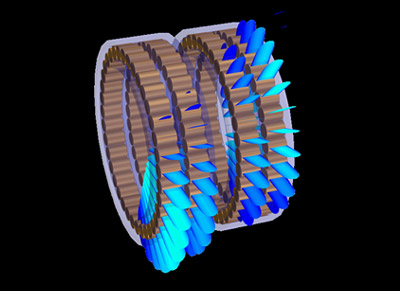

Perform advanced analysis of rolling element bearings to give unrivalled insight into bearing performance, enable optimal bearing selection and avoid premature bearing failures

All calculations are based on a fully-coupled flexible system simulation optimised for speed and accuracy and underpinned by a sophisticated non-linear bearing stiffness model

Accurately and rapidly predict static deflections, misalignments, loads, and stresses at different operating conditions

Analyse bearing stresses to the finest detail with the enhanced bearing contact analysis featuring a coupled strip model accurately capturing roller edge stresses, end effects, material yield, rib contact, and truncation

Accurate bearing stress including micro-geometry means you get the most accurate results from ISO 281, ISO/TS 16281, and other life prediction methods

Perform roller bearing time domain simulation to understand dynamic behaviour and avoid new, non-conventional failure modes such as bearing skidding

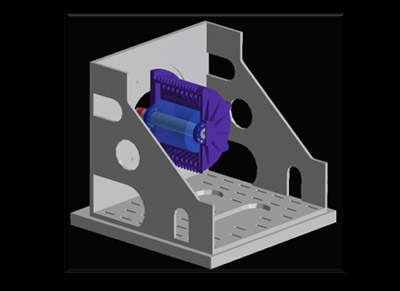

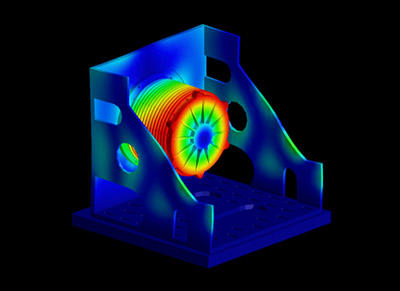

Romax Evolve

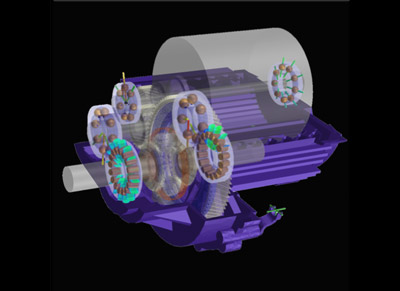

Romax Evolve: multi-fidelity tools for electrical machine design and analysis, from initial studies through to validation with test data

Model build:

Parameterised model build for rapid structural modelling

Comprehensive bearing catalogues

Create, import and condense FE housing components

Import/export geometry with leading CAD tools

Interfaces to electromagnetic FE software packages for electrical machine geometry and excitation import

Analysis:

Fast static analysis of electrical machine housing and shaft deflections

Evaluate bearings for durability and power loss

Calculate rotor-dynamic behaviour of rotor shaft system

Capture the effects of UMP on static and dynamic behaviour

NVH analysis of electrical machine including electro-mechanical excitation sources and rotor mechanical imbalance

Embedded acoustic solver brings complex simulation of radiated noise to the non-expert

Applications:

CAE led design – consider structural and NVH performance from the early stages to prevent problems before they arise

Support the design process from initial structural concept through to detailed housing design, test planning, and validation

Sits alongside other Romax Nexus products as part of a comprehensive toolchain for component and system-level analysis