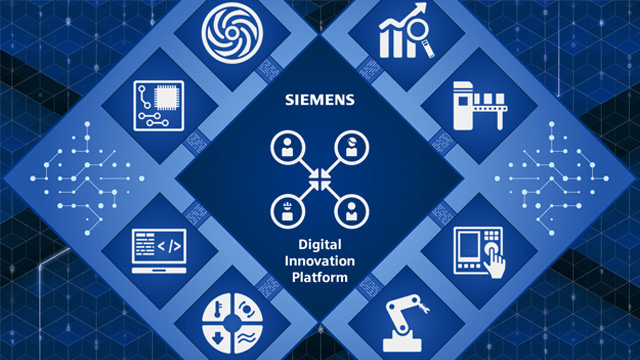

Siemens PLM (Product Lifecycle Management) software technology that enable innovations by connecting people across various functional process. It provides a platform that encompasses other digital tools like – NX for CAD/CAM SIMCENTER for CAE, Tecnomatix for Manufacturing planning, etc. PLM helps product manufacturers manage complex, cross-functional processes, coordinating the efforts of distributed teams to consistently and efficiently innovate and create the best possible products.

Product lifecycle management (PLM) is an information management system that integrates data, processes, business systems, and, people in an extended enterprise.

PLM software allows to manage this information throughout the entire product lifecycle efficiently and cost-effectively: from ideation, design, and manufacture to service and disposal.

Siemens PLM for Digitalization

As companies adopt digitalization as a strategy to transform their business they are faced with the need to address the broad set of processes across their organization with a consistent approach. Integrating these diverse processes into a cohesive, digital approach requires an underlying platform that has the breadth of capabilities to support all of the domains that constitute the customer’s enterprise.

Product Lifecycle Management (PLM) is a driver of successful product development, and a strategic contributor to business value across the enterprise. PLM helps product manufacturers manage complex, cross-functional processes, coordinating the efforts of distributed teams to consistently and efficiently create the best possible products.