Siemens Tecnomatix

Siemens Tecnomatix offers a comprehensive portfolio of digital manufacturing solutions that help you to digitalize manufacturing and the process of transforming innovative ideas and raw materials into real products. With Tecnomatix software, you achieve synchronization between product engineering, manufacturing engineering, production, and service operations to maximize your production efficiency.

Technomatix helps you to create a digitial twin of your facilities and processes and helps to do achieve first time right.

Intosite

Navigate Digital Twins of Your Production Facilitiesallows you to create cloud-based 2D/3D/panoramic representations of a production facility, presented in its geographical context. This allows you to navigate through the facility in a simple and familiar way providing intuitive access to information from any IT system.

Intosite facilitates a virtual tour of your facilities using rich visualization techniques, with the ability to get relevant information by simply clicking on visual tags that are connected to PLM and other IT sources

Human Modeling

Tecnomatix human modeling and simulation, you can improve the safety, efficiency, and comfort of your workplace environment using Jack and Jill virtual humans. Human-centered operations can be analyzed with lifelike models that can be scaled to match different population characteristics.

You can test design and operational aspects of a wide variety of human factors, including injury risk, timing, user comfort, reach-ability, line-of-sight, energy expenditure, fatigue limits, and other important parameters. This helps you to ensure compliance with ergonomic standards during planning and to avoid the discovery of human performance and feasibility issues during production.

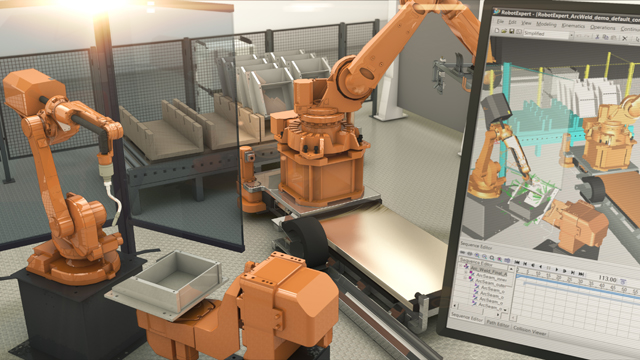

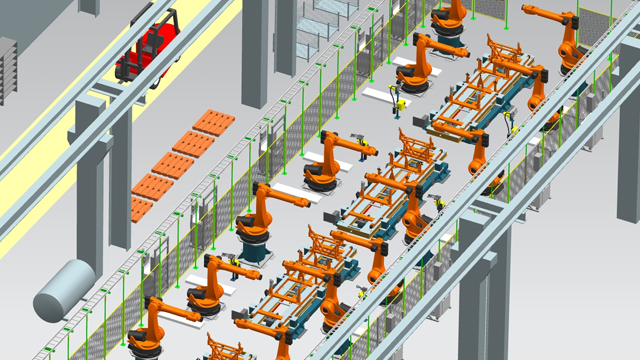

Offline Program Robotics

Design, simulate and offline program operations utilizing robotics and automation.

Tecnomatix robotics and automation programming solutions address multiple levels of robot simulation and workstation development, from single-robot stations to complete production lines.

Market pressures and structural costs are requiring manufacturers to build more automation and increased flexibility into their production facilities. Individual plants need to increase the number of products they can build, while exceeding their current quality targets and optimizing their shop floor footprint. Manufacturers must rely, more than ever, on robotics and automation systems to gain flexibility for more complex manufacturing operations and to boost their production efficiency.

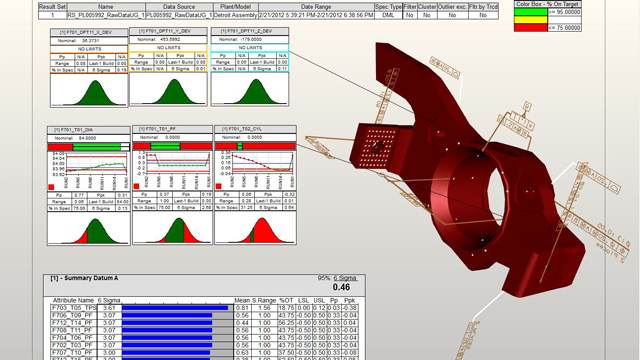

Variation Analysis - VSA

With the highly complex products of today, dimensional variation can consume enormous amounts of time and effort to control. The specified tolerances of single parts can easily lead to issues during assembly, which is a costly time to make changes. Variation Analysis can help reduce the negative impact of variation on product dimensional quality, cost and time to market.

Factory CAD & Line Designer

Design Factories Digitally , Design assembly lines, equipment and tool requirements in a 3D environment. Optimize factory space and maximize capital resource utilization by digitally configuring factory layouts.

With Line Designer you can quickly design and visualize layouts of production lines and associate them to manufacturing planning.

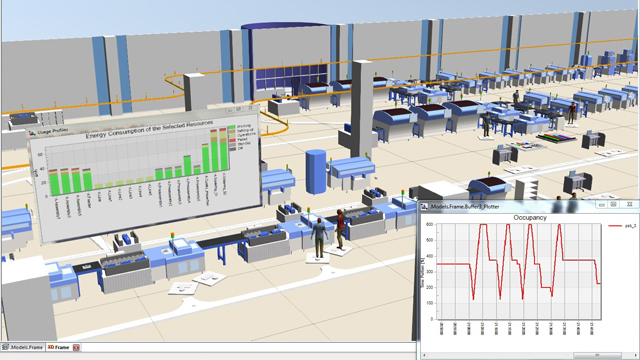

Plant Simulation & Factory Flow

With Tecnomatix logistics and material flow simulation, you can use discrete event simulation and statistical analysis capabilities to optimize material handling, logistics, machine utilization, and labor requirements. This allows you to quickly check for bottlenecks, validate transported materials, and view resource utilization over time for multiple process alternatives.