3D Print Pod Prototype is a part of the International Hyperloop Pod Competition hosted in Valencia 2021. From the mind of Elon Musk, the motive was to create the fifth mode of transport was born and then entrusted in the capable hands of university students all around the world.

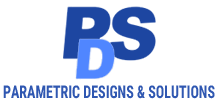

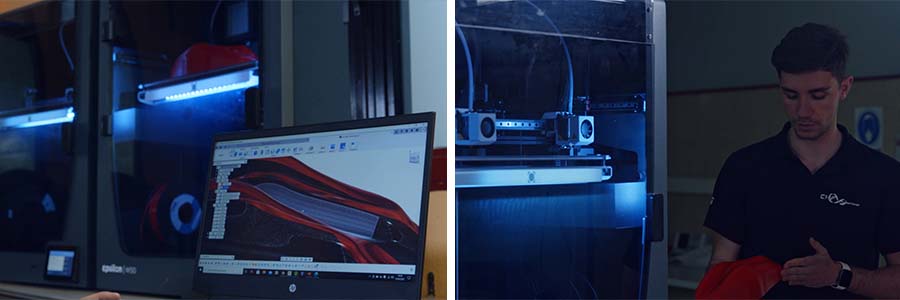

One of the most promising was Hyperloop CHF team which employed the use of the BCN3D Epsilon W50 and BCN3D materials for molding and end-use parts for their unique streamlined 3D printed POD prototype.

Objective OF Hyperloop Competition

The basis of the Hyperloop competition is to build upon the blueprint for a superfast train that will change the future of the way we travel. Essentially, passengers will be contained in a protective pod that ‘floats’ above the track, for a luxurious journey to reach destinations in record timing.

3D Print Pod Prototype to Accelerate Process

The ecosystem between the design programs and 3D printing technology was easy to introduce, faster, and more efficient and thus boosted their workflow. Saving time and money and having more freedom in their design gave Hyperloop CHF the upper edge they were looking for.

3D printed end-use parts were also included directly in the stabilization system. Wheels were printed in TPU for its ability to withstand high temperatures and its strength. The brackets were made of carbon fiber for a sturdy, reliable support system. Hyperloop CHF explored a variety of different materials to see how the properties could advance their prototype. They came to the conclusion that ABS would perform best in this case for its high-temperature resistance.

The team was proud to be one of only 4 out of 11 teams to pass all the tests, an extra impressive feat as the only team from a vocational training center to make it to this stage. The next move for the finalists is to persevere with their goal of reaching 550kmph and improve by focusing on the propulsion system and outer shell. An invaluable learning curve that has equipped the students with the knowledge of 3D printing design and production and set them up for a future of making waves in Industry 4.0.