Parametric Designs & Solutions represented BCN3D Technologies in the 7th PlastAsia 2022 event.

To provide the latest technologies in the field of 3D-Product Design, Tool Design, Simulation, Cost Control, Engineering Data Management and Manufacturing and help organizations achieve maximum business benefits.

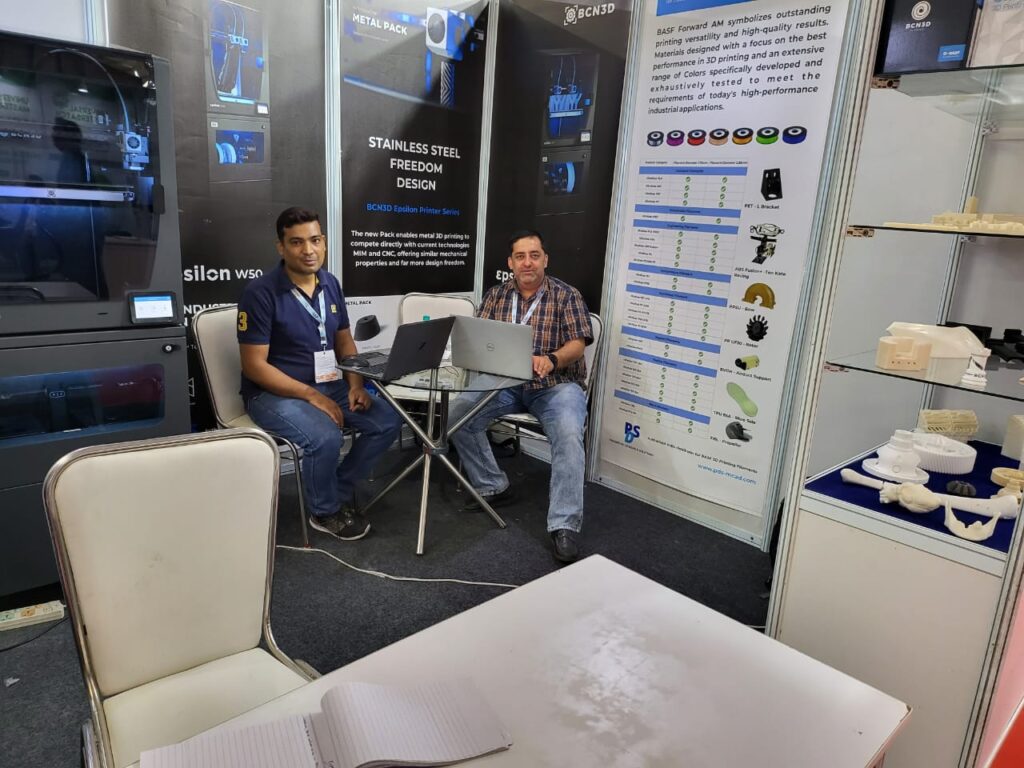

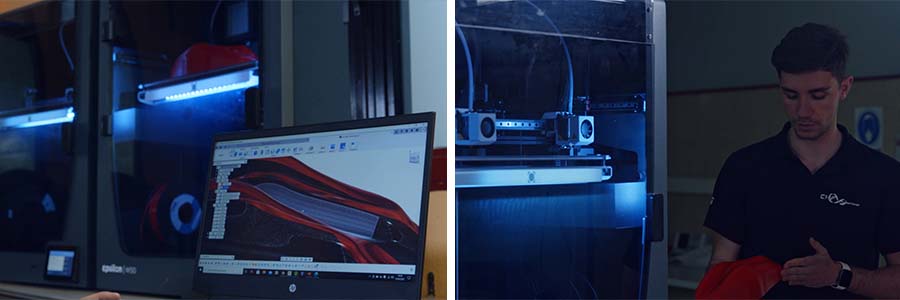

We hosted a Live Demonstration of BCN3D Printers, Sigma D25 along with Epsilon Series W50 SC for our guests in the event.

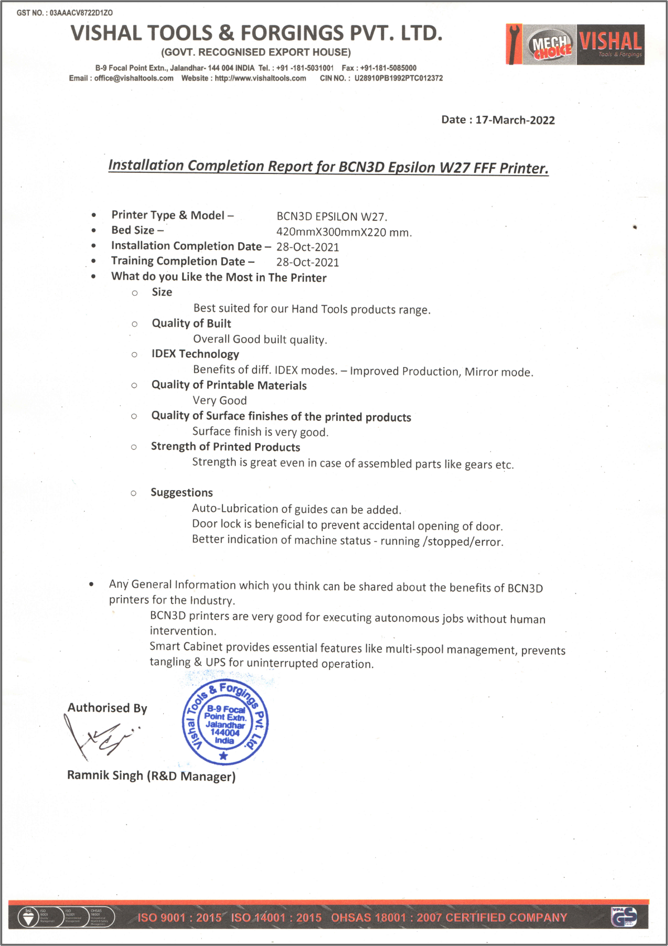

Being an authorized business partner for BCN3D Spain for their Unique and class first IDEX based FFF 3D printers.

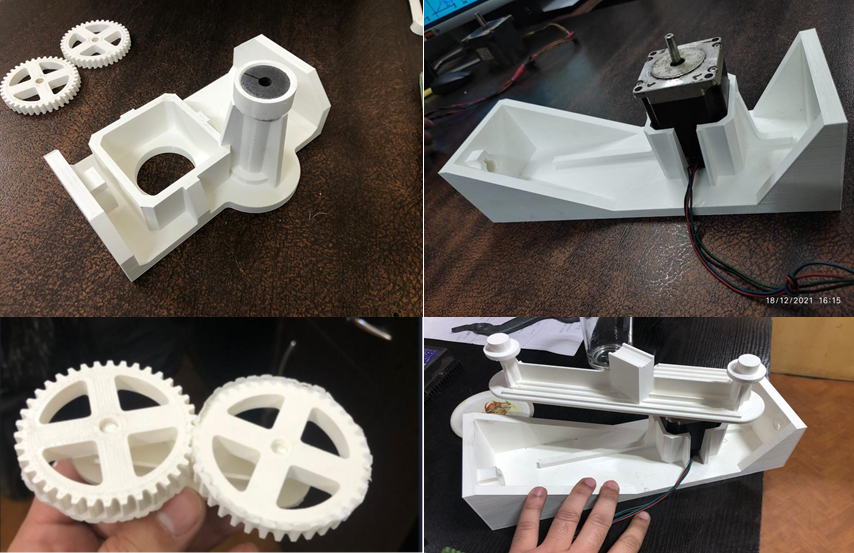

We showcased a good amount of new opportunities and technologies available through BCN3D printers to our guests. Demonstration was live throughout the day of the event for our clients to understand the technology.

Parametric Designs & Solutions team was available in the booth for all our walk-in guests along with suitable materials and samples prepared to be showcased in the booth with reference to different segments of the Manufacturing Industry.

Below are some scenes from the event :