Siemens Teamcenter Product Cost Management supports cost engineering in designing and implementing specifications at the lowest total cost of ownership, and lowest carbon emission, and in balancing the design with the costs of procurement, manufacturing, and assembly. With the provided robust database, benchmark data, and analytic capabilities, product and tool costs can be calculated with near-surgical precision.

With Teamcenter Product Cost Management version 9.3, we have further expanded our capabilities enabling customers to benefit from the latest innovations. With the following, I’d like to share with you some of the main improvements.

Siemens Teamcenter : Optimizing product, and carbon emission strategies through environmental and economic transparency

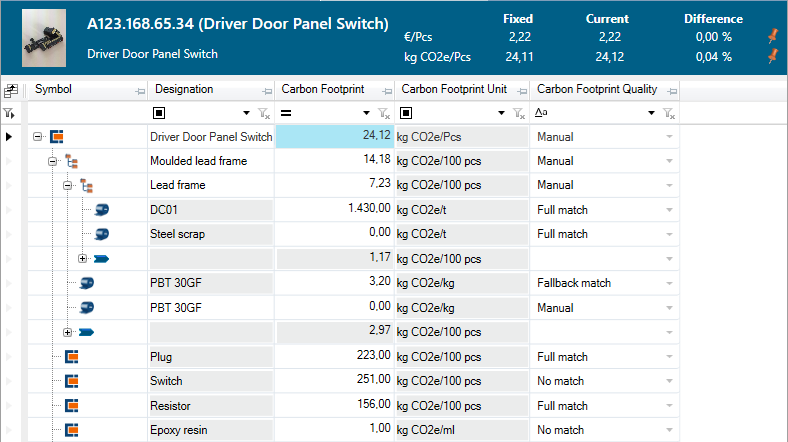

The carbon footprint calculator for Siemens Teamcenter Product Cost Management 9.3 provides the opportunity for cost engineers to calculate carbon emission along with their cost calculations. Teamcenter Product Cost Management supports the calculation of emissions for energy usage in production systems, calculation of emissions based on used raw materials, purchased parts, and material compositions. This is then rolled up the assembly tree for a result.

The carbon footprint calculator is aimed to be used at the early stages of the product life cycle within the development process, and not after the start of production where typically legacy systems take the lead from then onwards. The emission factors are hosted in the multidimensional master data (with dimensions like region, customer, supplier, date, or any other), and the solution looks up the best value for the end-user depending on the calculation parameters. The final goal is to allow cost engineers to manage a full roll-up, for both, cost and carbon footprint predictions. Teamcenter Product Cost Management supports you in analyzing the cost and environmental footprint of a product at each stage of the development process which provides greater transparency, enables smarter trade-offs, and informs stronger CO2-emission strategies.

Accurate “should cost” calculations with improved and extended knowledge database

Siemens Teamcenter Product Cost Management 9.3 introduces an updated and extended database which, improves cost engineers and procurement productivity, and increases data query performance.WATCH THE ON-DEMAND WEBINAR “Identify savings potentials in procurement with knowledge-based cost engineering”

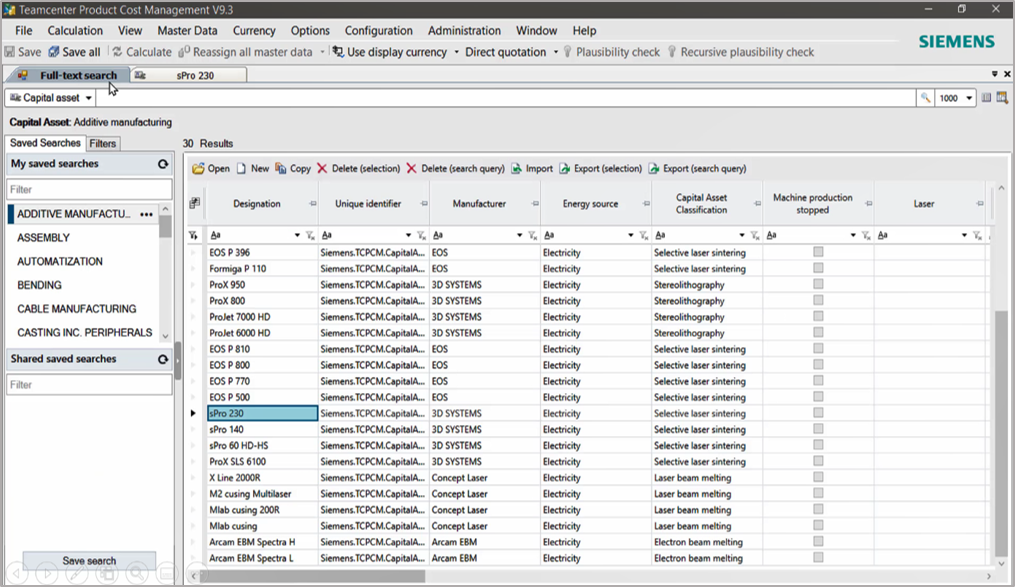

Updated global production site and machine data

We continuously update our location database with the latest actuals for wages and labor burden, prices for natural gas and electricity, rental costs, and interest rates. With version 9.3, 65 countries and a total of 543 regions within the Americas, APAC, and EMEA with new global location data are available. We also implemented an “overview at a glance” for selected countries which provides insight into our research methodology. The machine data content is enhanced frequently. There are also new rubber injection molding machines added to the database.

Extend global reference data by material prices and overhead rates

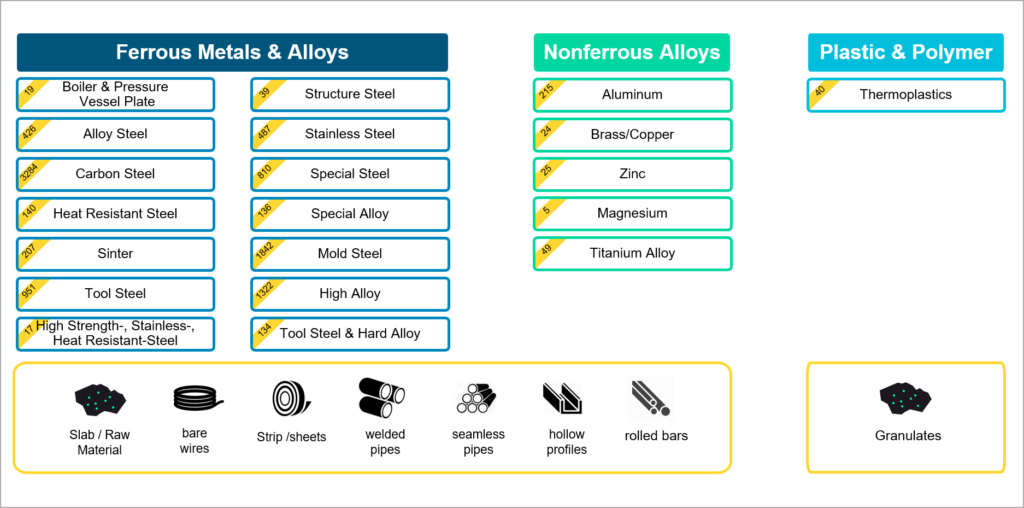

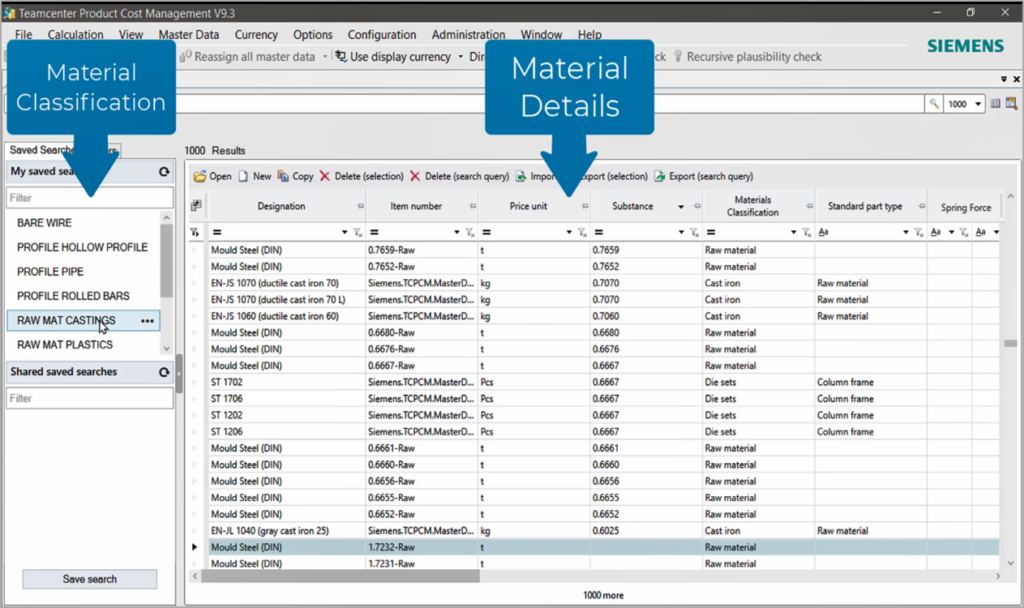

The key factors for successful “should costing” are the right material prices and overhead rates. Therefore, there is a new full-fledged global reference data module that includes raw material prices and industry average overhead rates.

In version 9.3, there are 10,000 ferrous, nonferrous, and plastic materials. The material prices and overhead data consist of more than 10,000 standard material prices for major standards of materials.

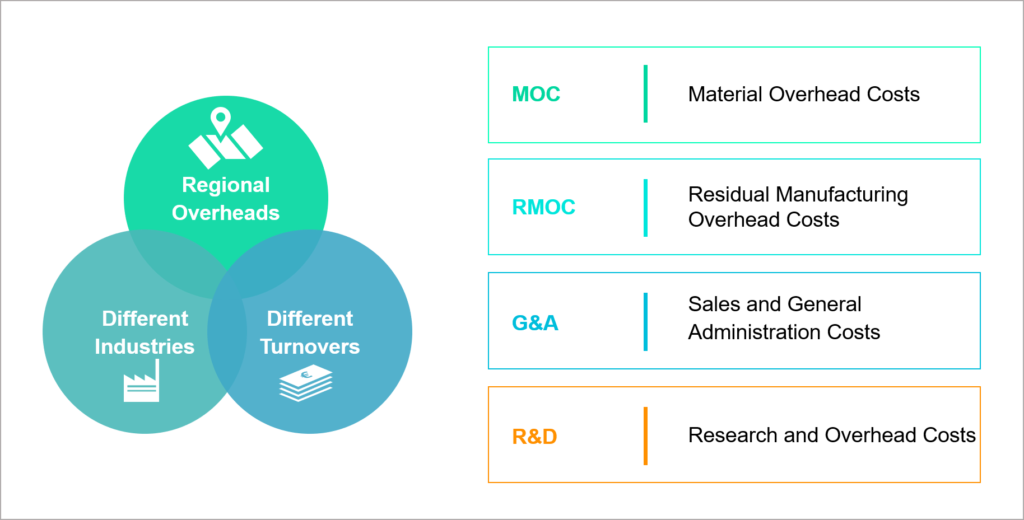

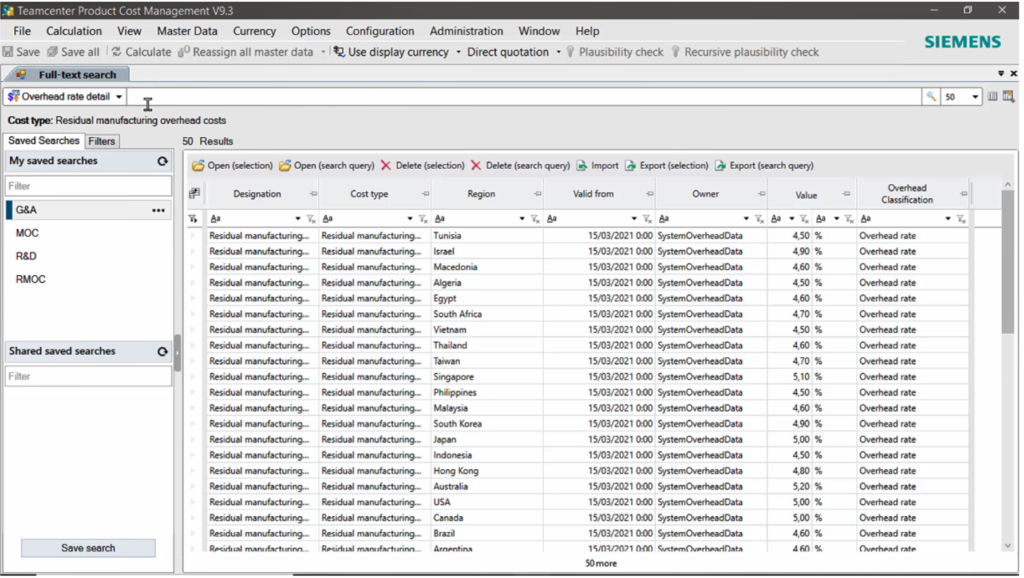

Furthermore, overhead reference data newly contains material overhead cost (MOC); residual manufacturing overhead costs (RMOC); sales, and general administration costs (G&A); research, and development cost overheads (R&D) from more than 65 countries. Customers that are dependent on the automotive industry will receive insights into automotive industry-specific material prices and overhead rates that are segmented on region level.

Updates are made 1-2 times per year on reference data: production sites, substance, machines, overheads, and knowledge domain processes data. On the new material prices data, the updates are provided 4 times per year.

Try to imagine doing this on your own… What will be the cost be? How many opportunities would you be missing out on? With the value provided by Teamcenter Product Cost Management 9.3, you can save time and money by leading the research on your own and completing “should cost” calculations much faster.

Precise quotes by supporting custom list-properties in project assumptions during multi-year lifetime calculation

With version 9.3, you can select for every item in the project assumptions custom list properties that are used in lifetime calculation. This capability provides you an extra dimension in quotation and control of prices used in the lifetime calculation. More precise quotes are provided since project-specific custom list properties can be selected for material, cost factors, and exchange rates.

Quick quotation solution for toolmakers as software-as-a-service (SaaS) offering

The NX Mold Connect application (available October 1st) is a cloud-native collaboration platform for designers and mold makers to facilitate injection molded part manufacturing by design validation and cost estimation. Within the SaaS solution NX Mold Connect, you can execute different designs for manufacturing analysis. You can also perform feature recognition analysis like NX Feature2Cost. With the analysis of the part, ribs, undercuts, and openings will then be determined. These values can be used for a quotation in Teamcenter Tool Costing.

Further improved and new capabilities in Teamcenter Product Cost Management

Teamcenter includes further enhancements and new capabilities to support improved usability and increased performance, such as automatic saving of the table configuration on the user level, new master data documents in the new user interface, and much more.

With the new updates, you can balance emissions with cost impact across the entire product portfolio. Further, you can lead short and long-term cost and carbon footprint scenario planning by monitoring product-cost impact over time, including market dynamics.